VALUE ADDED SERVICES

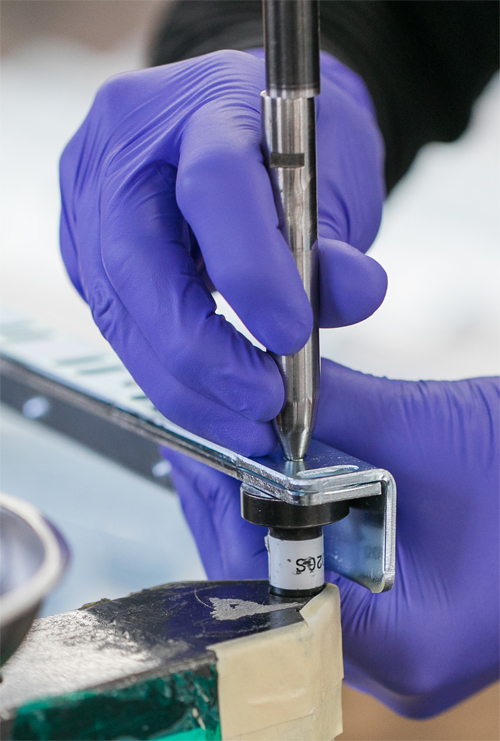

In response to industry demands, MASS Precision offers advanced electronic assembly services. This dedicated segment of our facility now spans 32,000 sq. ft., with 12,000 sq. ft. featuring built-in ESD flooring. This specialized area focuses on system integration and the manufacturing of complex electro-mechanical assemblies, catering to the leading OEM manufacturers in Silicon Valley.

DESIGN, ANALYSIS AND WORK CELLS

Our comprehensive offerings include design, engineering analysis, and support, seamlessly integrating our sheet-metal expertise with various contract manufacturing services. These services encompass custom-designed power supplies, backplane assemblies, complex printed circuit boards, and cabling systems. Our Flexible Work Cells structure allows us to swiftly expand to thirty product lines, incorporating Lean Manufacturing, Kanban, and Continuous Flow methodologies. We also develop tests in response to customer requirements, enhancing our conventional Hi-Pot and Ground tests.

TODAY’S MARKET PLACE

MASS Precision serves the rapidly evolving businesses in today’s electronic marketplace, addressing needs from quick-turn prototypes to high-volume production. Speed defines our marketplace, and flexibility is our response. We operate in parallel across all phases of a product’s manufacturing, from design implementation through final shipment, without compromising on quality or service. In today’s competitive landscape, our engineering, prototyping, testing, and production initiation processes are streamlined to shorten our customers’ product development cycles, allowing them to innovate and advance in new markets.

PACKAGING

MASS has the capability to procure and design custom packaging to suit the needs of our Customers Project for both local and International deliveries.